What Glue Is Best to Ballast My Ho Scale Railroad Track

Model ballast can be sourced in a variety of grey shades from various manufacturers. The ballast isn't just a uniform colour, but has a subtle blend of dark and light stones because ballast often has crystalline or darker impurities.

The traditional method of fixing ballast is to apply a 50:50 ratio of PVA and water, with a drop of washing up liquid. When applied, the diluted glue trickles through the ballast and dries to hold everything in place. This method uses a powdered glue, which is mixed with the ballast before it is laid. This mixture is then sprinkled over the track, and water is sprayed to solidify the glue. This method dries faster, but whichever you choose, take your time to guarantee a neat finish.

Expert tip - why use washing up liquid?

If you choose the traditional ballasting method of mixing water and PVA glue in equal measures, adding a drop of washing up liquid is advised. This removes the surface tension when applying the glue and helps it soak into the ballast more easily.

Content continues after advertisements

1

Add seven parts of ballast to one part of powdered ballast glue.

.jpg)

2

Mix the ballast and glue powder thoroughly until both blend to one uniform colour. A paint brush handle is a good tool because it'll reach the corners of the glass.

.jpg)

3

Tilt the jar at an angle until the ballast and glue mix is at its edge, then tap the side of the jar with a finger and evenly spread the mixture.

.jpg)

4

You'll find some areas are coated with the mixture, despite your best efforts to avoid them. All is not lost, however.

.jpg)

5

Use a large soft paint brush to distribute the ballast evenly across the track and away from moving parts like point blades uncoupling ramps.

.jpg)

6

Fill a spray bottle with tap water and gently mist the area of track. It can take a while to soak in, so be patient.

.jpg)

7

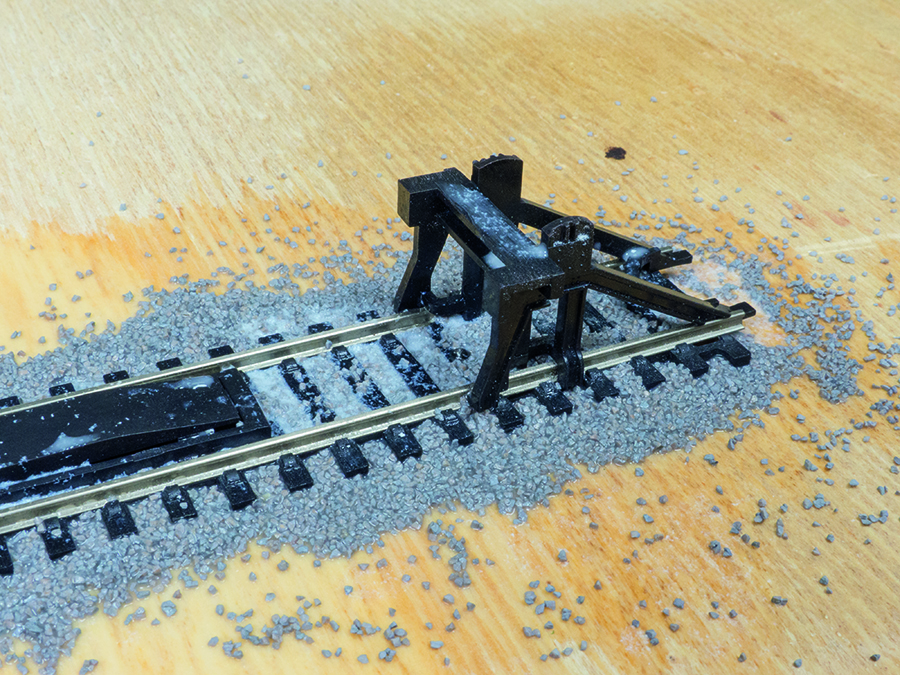

The glue will rest on areas where powder has landed as soon as the water hits it. Areas of plastic like this ramp and buffer stop can be carefully wiped, but avoid touching the sleepers until the glue is dry.

8

When dry, it's time to start cleaning the sleepers. It's important that moving parts are kept free from debris, so a paper clip opened up is a great tool to run between rails

.jpg)

9

The crossing 'Vee' or 'frog' of the point must be clear of ballast too, so spend some time on this area, removing stray granules.

.jpg)

10

The contacts of the point are fragile, but rely on touching the rails so that electricity can flow. Ensure these are free and that parts move freely.

.jpg)

11

You can now remove stray ballast from the top surface of sleepers. I find scraping them with the back of a craft knife works well.

.jpg)

12

Last, but not least, you can now connect the wires from your controller to the power clip. Each loop of track requires a power clip and feed of electricity to work.

So, in 12 easy-to-follow steps it's possible to make your track mirror that of the real thing. This is something that anyone who is constructing a model railway should do to achieve a realistic look.

BRM magazine prides itself on offering easy-to-follow expert modelling advice. To see our latest money-saving subscription offers, click here.

What Glue Is Best to Ballast My Ho Scale Railroad Track

Source: https://www.world-of-railways.co.uk/techniques/how-to-ballast-track/

Publicar un comentario for "What Glue Is Best to Ballast My Ho Scale Railroad Track"